Explain copper bar classification, copper bar production process and characteristics

Release time:2021-01-20Click:1063

Copper bar is a kind of high current conductive product, which is suitable for high and low voltage electric appliance, switch contact, distribution equipment, busbar slot, etc. . The electrical copper bar has the advantages of low resistivity and large bending degree.

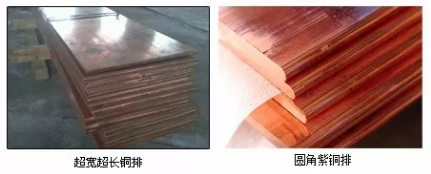

Copper Bar, also known as copper bus bar, copper bus bar or copper bus bar, grounding copper bar, is made of copper, rectangular or chamfered (fillet) rectangular section of the long conductor, made of aluminum materials known as the aluminum bar, to Act as a current carrier in a circuit and to connect electrical equipment.

Copper bars are widely used in electrical equipment, especially in complete sets of distribution equipment, because copper bars have better electrical conductivity than aluminum bars, and they are generally used in a, B, C, n phase bus bars and PE bus bars in distribution cabinets In use, the copper row is generally marked with the color letters or painted with color paint, a phase copper row is marked with "yellow" color, b phase is marked with "green" color, c phase is marked with "red" color, n phase is marked with "light blue" color, PE bus bar is marked with "yellow-green" color.

Copper bar is mainly used in primary line (high current phase line, zero line, ground wire will be used copper bar) , in the cabinet on a large current of primary components are connected with copper bar, for example, a row of cabinets and cabinets are connected between the main bus bar, the main bus bar to each side of the Switch Electric Cabinet (disconnector, circuit breaker, etc.) is the branch bus bar. The copper row has tin plating also has bare copper row, in the electric cabinet copper row connection place generally must do the tin plating processing and the embossing processing or adds the conductive paste. The spare parts are protected by heat shrinkable sleeves, and some are painted with insulation.

1. Shaped Copper Bar

Compared with the Common Copper Bar, the cross-section shape is not a square rectangle, the shape is various, there are "l" type, "t" type, trapezoid, polygonal, mostly depending on the specific product design requirements of manufacturers.

2. Brass knuckles

Brass row has high strength, good plasticity, suitable for cold, hot processing weldability and corrosion resistance, good mechanical properties, good plasticity in hot state, good machinability, weldability and corrosion resistance, called Ordinary Huangtong, by two or more elements called special brass, the fundamental composition of the elements and copper composition of the proportion, its performance is also different. At the same time brass row according to its actual demand can be made into different specifications.

Brass row with high strength, good plasticity, suitable for cold, hot processing weldability and corrosion resistance good, condensation and heat pipe, snake-shaped pipe, Siphon pipe, cooling equipment parts, have good mechanical properties, good plasticity in hot state, good machinability, weldability, good Corrosion Resistance, a variety of deep extension and bending force pieces, such as pins, nuts, pressure gauge springs, heat dissipation, ring pieces.

The mode of production and features of copper bar

Copper mode of production, process flow, features 1. rolling-sawing method Ingot heating-hot rolling-(milling-cutting-cold rolling-annealing) pickling-cold rolling-sawing-corner treatment-finishing straightening-cutting sizing-packing-storage, performance indexes can be well controlled, but there are flying edge and sawdust pressing, non-rounded corner, surface is not smooth enough, width tolerance is large, can not meet the high precision requirements, production costs are higher 2. rolling-drawing method, ingot heating-hot rolling-milling-cold rolling-shearing-annealing-pickling-drawing-finishing straightening-cutting sizing-packing-warehousing, various quality indexes can be well controlled, production cost is low, but shearing flash and tolerance are difficult to control 3. Profile rolling method, iron Mold Red ingot-hot (warm) rolling-pickling-rough rolling profile-annealing-pickling-finishing rolling profile-finishing straightening-cutting sizing-packing-warehousing, performance indexes can be better controlled, mill rolls are more, production cost is higher 4. extrusion-stretching method, heating-extruding-drawing-annealing-pickling-drawing-straightening-cutting-sizing-packing-storage of Ingot, annealing and pickling processes are added to ensure 180 ° bending property and better control of Quality Index. The working procedure is simple, the efficiency is high, the production capacity is large, but the production cost is high. 5. Up Drawing (or horizontal) continuous casting -- rolling -- drawing, up drawing (or horizontal) continuous casting -- cold rolling -- ANNEALING -- pickling -- drawing -- finishing straightening -- cutting length -- packing -- storage, but the performance index is not as good as other methods, the specification is limited, the efficiency is low, the productivity is small

Source: Copper Aluminum Online

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.