The research and application of cu-ni alloys are reviewed from the aspects of classification, properties, applications and requirements of cu-ni alloys

Release time:2021-06-18Click:1014

ABSTRACT: The rapid development of marine industry requires more and more marine engineering materials, including white copper, which is widely used in ships, some power plants and seawater desalination. Because of the long-term seawater erosion corrosion, if the corrosion resistance does not meet the use requirements, corrosion failure will occur, resulting in huge losses. Therefore, cupronickel has excellent seawater corrosion resistance (especially good erosion corrosion resistance) and corrosion fatigue resistance, excellent cold and hot processing properties, as well as high tensile strength, yield strength and other properties have attracted increasing attention.

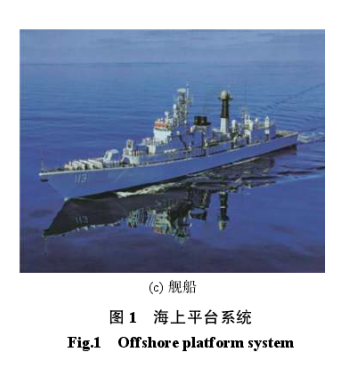

Key Words: Cupronickel; composition; Corrosion Resistance; application classification number: TG146.15 literature symbol: a with the development of marine industry, seawater cooling system materials were selected from early TUP copper, aluminum brass, stainless steel, cU-NI alloy with good seawater corrosion resistance has been developed. Nickel is the main element of Cupronickel, and a small amount of FE, MN and other elements can form a continuous-single-phase solid solution, so that it has good ductility, impact and thermal stability. At the same time, the infinite solution of Cu-ni makes the phase transformation of cu-ni alloy not happen in the later cold and hot working, so the mechanical properties and corrosion resistance of the alloy are little affected. This paper introduces different cupronickel alloys and their applications, and summarizes the research progress of cupronickel alloys. Figure 1 shows the offshore platform system and figure 2 shows the material performance requirements.

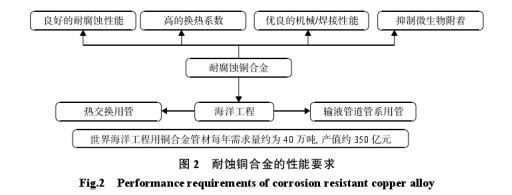

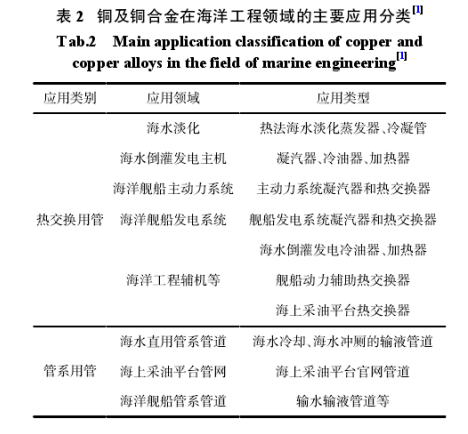

1. The classification table 1 of copper-nickel alloy is the grade and element composition of cupronickel alloy. Cupronickel can be divided into manganese cupronickel, iron cupronickel, common cupronickel, aluminum cupronickel and zinc cupronickel, the context of the application is different. Due to its irreplaceable corrosion resistance and many properties superior to the traditional alloy, so it has a greater application potential.

2. The properties and applications of copper-nickel Alloys Common Cupronickel is generally a structural copper-nickel alloy. In addition to having high corrosion resistance, it has better comprehensive mechanical properties at high and low temperatures, i. e. good plasticity and toughness, generally used as a bar or strip. At the same time, the addition of some trace alloying elements such as Fe, MN, Zn and AL on the basis of ordinary cupronickel can meet the special performance requirements of practical application and better meet the industrial requirements. The most widely used iron cupronickel is BFe10-1-1(C70600) and

BFe30-1-1(C71500) , when the mass fraction of Ni is 30% and 10% , the passivation interval is wider and the corrosion resistance is the best. The alloy is also known as "Marine Engineering Alloy" for its excellent resistance to seawater erosion and corrosion. The main applications of copper and copper alloys in marine engineering are shown in Table 2. BFe10-1-1 and BFe30-1-1 alloys have the advantages of good resistance to seawater erosion and corrosion, high heat transfer coefficient, excellent mechanical/welding properties, inhibition of adhesion of marine microorganisms, etc. , widely used in cooling water pipes of marine main and auxiliary engines, fire fighting pipes of offshore oil platforms, heat exchangers of power plants, condensers of Binhai nuclear power stations, salt water heaters of multistage flash units for seawater desalination [2-4]. BFe30-1-1 alloy has higher strength and is also used in high strength structures such as shafts, fasteners, valve stems and flanges in some offshore installations. The development of BFe30-2-2 alloy with good erosion-corrosion resistance and sand-corrosion resistance in seawater is to solve the problem of high sand content in seawater in the east China Sea. BFe10-1-1

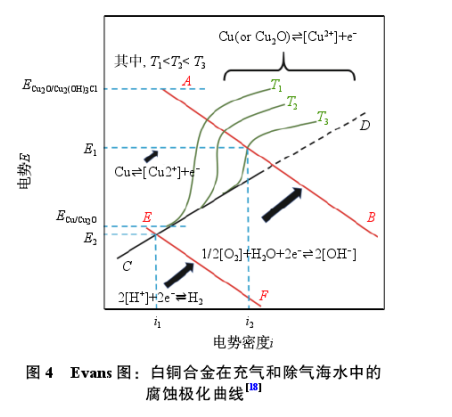

The tensile strength ≥370MPA, yield strength ≥150MPa, elongation ≥18% , vickers hardness ≥85, corrosion resistance: Corrosion rate (50 °C, 3.5% NACL seawater)≤0.025MM/A, and hardness of BFe30-1-1 alloy tubes should be higher than that of BFE30, no pitting allowed. Manganese white copper (BMN3-12 alloy) has moderate resistance coefficient, small resistance temperature coefficient and relatively stable, because of its good electrical properties, BMn3-12 alloy can be used to make standard resistance and other precision instrument resistance components. With the development of the time, the precision of the instrument is required more and more, so the research on the alloy can not stop at changing the composition and content of the alloy. The BMN3-12 alloy has a special coherent twin boundary by Annealing, horizontal extrusion and drawing, which can improve the strength of the material without affecting its conductivity. BMn40-1.5 alloy is an electrical copper-nickel alloy which was used earlier than BMn3-12 alloy. Because of its low temperature coefficient of resistance, it has good heat resistance and can be used in a wide temperature range. Compared with BMn3-12 alloy, BMn40-1.5 alloy has higher thermoelectric potential to copper, so it is suitable for AC precision resistance, sliding resistance, starting, regulating transformer and resistance strain gauge. Aluminum Cupronickel has both high strength and good plasticity and toughness. Among them, BAl13-3 alloy is often used to make corrosion-resistant parts with high strength, and BAl16-1.5 alloy is used to make flat spring with important use. For a long time, in order to improve the service performance of aluminum white copper, a small amount of micronutrient is often added to strengthen the matrix of aluminum white copper. Because of its high strength, high conductivity and good wear resistance, al-cupronickel can be used as a potential material for lead frame and wear-resistant parts. Zinc cupronickel (BZn18-18BZn15-20 alloy) is also called "German silver" [12] . Due to its excellent tensile strength, fatigue resistance and corrosion resistance, zinc cupronickel is mainly used as the housing of components or crystals, medical appliances, building materials and wind instruments. 3. With the rapid development of China's marine shipbuilding industry, Marine Oil and gas industry, marine mining industry, marine electric power industry and seawater desalination industry, the demand for copper-nickel Alloy Properties has become higher and higher. The copper-nickel alloy tubes are widely used, and the copper alloy condensing tubes used in ships have been working in seawater environment with high temperature, high pressure and high corrosion. Therefore, it is not enough only to meet the requirements of chemical composition, mechanical properties and seawater corrosion resistance of the products, but also to strictly require such indexes as geometric size accuracy, technological properties and internal organization, at the same time, the copper-nickel alloy pipe is required to have good corrosion resistance, high heat transfer coefficient, large diameter, high precision, excellent mechanical welding technology, and better inhibition of the adhesion of marine microorganisms. At present, domestic processing equipment problems, leading to large-caliber copper tube alloy can not mass production, mainly rely on foreign imports. Therefore, the production difficulties of large-caliber copper tubes still need to be overcome. 4. Progress in research on cu-ni alloys 4.1 corrosion mechanism of cu-ni alloys Fig. 4 shows various corrosion processes of cupronickel in oxygen-containing seawater and Ab line shows the CATHODIC reaction of cupronickel in seawater, it can be expressed as: 1/2[ o 2] + [ h 2O ] + 2e something = 2[ Oh something ](1) the CD line in Fig. 4 is an anodizing process in which cupronickel does not passivate in seawater. The curves t 1, t 2 and t 3 of Cu = cu + e something (2) are the anodic reactions of Cupronickel passivated in seawater. The EF wire is a hydrogen evolution reaction of Cupronickel due to oxygen deficiency, so there is neither passivation nor corrosion product in this process. Cu (orCu2O) = cu2 + + 2E something (3)

2[Cu2] 3[OH?] [Cl?]=Cu2(OH)3Cl (4) 4.2 Research on the Corrosion Resistance of Cu-Ni Alloy In order to meet the requirements of Marine materials, a great deal of research has been done to improve the corrosion resistance of Cu-Ni alloy. Deng Chuping et al. [19] found that the tensile strength and elongation of white copper with the addition of rare earth Ce were improved, and the grain structure was more compact. Moreover, the addition of rare earth Ce could improve the typical corrosion tendency of nickel removal of the alloy in sulfur-containing media. Jiang et al. [20] studied the effects of different Fe content on the microstructure and properties of B10 alloy, and found that the corrosion resistance increased first and then decreased with the increase of Fe content, but the corrosion resistance mechanism was not further studied. Zhang Jiaying [21] from Beijing Nonferrous Metals Research Institute found the optimal alloy ratio to improve the corrosion resistance of B10 by controlling the Fe/Mn ratio. The study found that when Fe/Mn=3:2, the corrosion resistance of the alloy was the best. Ma et al., Chinese Academy of Sciences [22] found that the recrystallization annealing process of solid solution cold rolling can increase the number of grain boundaries and twin boundaries, and thus the alloy with good corrosion resistance can be obtained. 5. Conclusion in this paper, mainly copper and nickel alloy as the breakthrough point, this paper expounds the different copper nickel alloy chemical composition and its applications, this paper introduces the domestic and foreign famous copper condenser pipe production factory, domestic Marine system piping with copper and nickel alloy tube performance requirements and future development trend in the copper and nickel alloy, summarizes the main research progress of copper and nickel alloy At present, the corrosion resistance of Cu-Ni alloy is improved mainly by adding trace rare earth elements, adding different content Fe elements, changing the ratio of matrix alloying elements and grain boundary engineering.

Source: CNKI Author: Lu Jing

Disclaimer: Some pictures and texts on this site are collected from the Internet and are only for learning and communication. The copyright belongs to the original author and does not represent the views of our site. This site will not bear any legal responsibility. If your rights are violated, please contact us to delete it in time.