Analysis of technical difficulties in connection between copper terminal and aluminum conductor

Release time:2021-01-27Click:1026

1.Copper wire has always been the main carrier of transmitting power and signal current in automobile electric system. With the increasing requirement of energy conservation and environmental protection, and the increasing cost pressure in the industry, it has become a trend to look for lightweight and low-cost conductors to replace copper conductors. The conductivity of aluminum is next to that of copper, its specific gravity is only 30.13% of copper, and its price is relatively stable, only about 30% of copper. Therefore, it is an ideal substitute for copper wire and is favored by the industry. Especially, it has a good effect of reducing weight and cost when it is used in long power cable with large diameter. At present, many main engine factories are trying to apply aluminum wire to the whole car wire harness in batch. In consideration of the strength of the aluminum material, the two ends of the aluminum wire are still connected to other electrical equipment through the copper terminal. The connection between large-diameter aluminum wire and copper terminal mainly has the following 3 forms:

1. Ultrasonic Welding Connection

2. Friction Welding Connection

3. Plasma solder joint

2.Body text

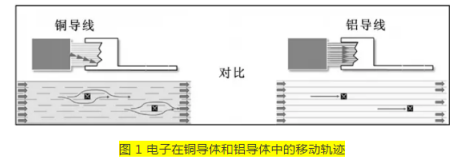

1. 1.1 there is a strong affinity between aluminum conductor and oxygen in the surface of aluminum conductor. Even at room temperature, the moment it touches air, its surface forms a dense aluminium oxide. The oxide film is only 2 nm thick and is tightly bonded to the surface of the aluminum substrate. Compared with copper conductors, the Oxide Film on Aluminum conductors prevents oxygen from diffusing into them and provides good corrosion protection in the atmosphere. But its good insulation prevents electrons from moving from one aluminum substrate conductor to another, meaning they can only move within the substrate itself. Because of this feature, the aluminum conductor end in the removal of insulation sheath, contact with the air surface of the aluminum conductor formed an oxide film. As shown in figure 1, electrons in an aluminum conductor can only move through a single aluminum wire, not between the wires. If there is partial wire breakage in a bunch of aluminum wires, the electronic movement in these wires will be interrupted, and the resistance will increase and the conductivity will decrease compared to the aluminum wire before the wire breakage.

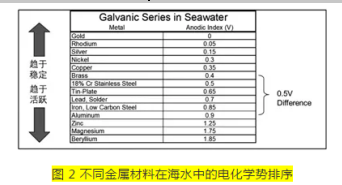

By contrast, the surface of the copper substrate conductor does not rapidly form a dense oxide film in the air, so even if a wire is broken, the electrons in the broken wire can still move forward through other copper wires. Therefore, from the qualitative point of view, copper wire in a certain proportion of the broken wire, although the conductive performance has decreased, but still can meet the use of requirements. 1.2 The electrochemical corrosion diagram of cu-al conductor contact part 2 is the sequence of electrochemical potentials of different metal materials in seawater. The chemical potential difference between Cu and al in seawater can be seen. When both metals are present in an electrolyte, a galvanic cell is formed and an electrochemical reaction takes place. Aluminum atoms in a low-potential aluminum material will leave the lattice and lose electrons, forming hydrated ions. Aluminum conductors exposed to this environment for long periods of time will be gradually eaten away, a phenomenon known as electrochemical corrosion.

When the humidity in the air is high or contains salt impurities, the ideal electrolyte environment will be formed, the copper terminal and aluminum wire direct contact part of the formation of the aluminum, as a negative electrode, copper as a positive electrode of the primary battery. As shown in figure 3, if the joint is not handled properly, serious electrochemical corrosion will occur and the electrical and mechanical properties of the copper-aluminum joint will be lost.

1.3 aluminum conductors whose electrical properties and mechanical strength are weaker than copper conductors whose conductivity is weaker than copper conductors at the same wire diameter are required to use aluminum conductors with a larger wire diameter than copper conductors, in order to reduce its resistance to the equivalent of copper wire electrical properties. In addition, aluminum conductor tensile strength, hardness and other mechanical properties are weaker than copper conductor, so it is not suitable for processing into aluminum terminal and other parts on the car, only consider using copper terminal and aluminum wire connection, however, mechanical damage or fatigue damage is easy to occur at the joint, so corresponding protective measures must be taken in application. 2 criterion for welding aluminum wire and Copper Terminal 2. 1 ensure good electrical properties at the welding site 2.1.1 ensure that the selected aluminum wire specifications are equivalent to copper wire the current industry commonly used copper wire standard is ISO6722-1[1] , aluminum wire standard is ISO 6722-2[2] . The equivalent substitution of aluminum conductor must take into account the similar conductivity, current carrying capacity and reduction curve of copper conductor, so as to replace the conductor material and maintain the original circuit protection strategy. Table 1 lists the specifications of Aluminium and copper conductors that can be considered as equivalent alternatives. The table can be used as a reference for the equivalent substitution of copper-aluminum conductors.

2.1.2 electronic free movement between aluminum wires by ultrasonic welding is achieved by transferring high frequency vibration waves to the surfaces of two objects to be welded and causing the surfaces of the two objects to rub against each other under pressure, this results in fusion between the molecular layers (see figure 4) .

The method can effectively destroy the oxide film on the surface of aluminum wire and realize the free movement of electrons between different aluminum wire conductors (see Fig. 5) .

The layers are fused to achieve good electrical properties. The performance of automotive wire harnesses is evaluated using the Ultrasonic welding standard [3] . In this edition of the standard has given the copper terminal and aluminum wire welding, the evaluation method and criteria for the conductivity of the same copper terminal and copper wire welding. 2.2 cable assemblies with Good Mechanical Properties at the welding site are at risk of being pulled by external forces, especially for large cross-section battery wires, which often act directly on a single cable. For Electrical Circuits using aluminum conductors, the relatively weak mechanical strength is located near the welding connection area. For example, during the assembly of the battery wire, the operator may pull the wire to produce a straight pull in the direction of the wire or exert a tearing force perpendicular to the welding surface. Therefore, in the design of terminal structure, it is necessary to consider adequate protective measures to resist the straight tension and tearing force. In the USCAR38 standard [3] , the lower limits of the pull strength that must be reached when aluminum wires of different specifications are connected to copper terminals have been specified. For Large Wire diameters, aluminum conductors (≥10 mm 2) do not have an explicit lower limit for tearing strength (Peel Strength) in USCAR38, and the lower limit is usually recommended by the engineer of a complete vehicle factory. 2. 3 to ensure the good anti-electrochemical corrosion performance of the welding part, the key to prevent the electrochemical corrosion of the welding part of the copper terminal and the aluminum wire is to insulate the welding part from the humid or salinized environment. Two types of Ultrasonic welding seals are commonly used: double-wall heat-shrinkable Tube seals (figure 6) and hot melt adhesive seals (figure 7) . Both of these methods can meet the standard requirements in the final environmental verification test, but considering the fluidity of the glue in the injection cavity during the hot melt process, the wall thickness of the hot melt adhesive must be kept at least 2.5 ~ 3 mm, the connecting part of the terminal after the sealing treatment is too big to be used in the narrow space of loading environment. The Wall thickness of the double-wall heat-shrinkable pipe after heat-shrinkable treatment is 1 ~ 1.5 mm, so the double-wall heat-shrinkable pipe seal has a wider range of application.

The double-wall heat-shrinkable tube is commonly called the heat-shrinkable tube with adhesive tape. The outer wall shrinks after being heated at high temperature. The solid glue on the inner wall melts into liquid glue. The double-wall heat-shrinkable tube is commonly called the heat-shrinkable tube with adhesive tape, the solid glue on the inner wall melts into liquid glue and covers the surface of the terminal connection, the connecting part and the insulated skin of the conductor after full flow, and achieves the sealing effect after cooling and solidifying. The sealing effect of the joint can be evaluated by salt spray test. The criteria for its evaluation can be found in GMW3191[4] . 2. 4 Good manufacturability of the weld is ensured by Ultrasonic welding the surfaces of both materials to and fro at a certain pressure and frequency, and by high temperature melting of the surfaces by friction, and form a molecular layer of fusion. Normally the terminals are fixed to the welding equipment, and the wires move back and forth at high frequency relative to the fixed terminals. Therefore, the terminal needs to have a reliable structure to be fixed. The welding effect can also be evaluated by the direct tension requirement of USCar38 standard [1] and the tear force requirement recommended by customers.

Source: Harness China