Metal Knowledge Sharing, failure analysis of fatigue crack in copper alloy continuous extrusion die

Release time:2022-02-23Click:979

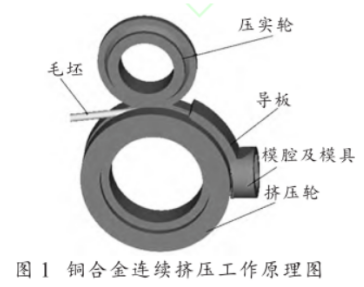

Foreword Continuous extrusion technology has been widely used in Non-ferrous metal industry due to its advantages of high efficiency, high quality and energy saving. Continuous extrusion has been applied to the production of copper and copper alloys, and copper flat wire and solid copper products have been produced with copper and copper silver alloys as billets. How it works is shown in figure 1.

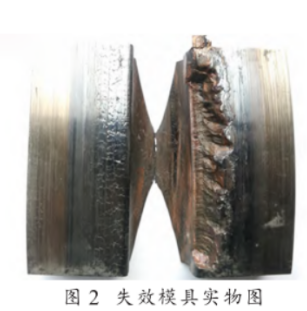

An extruding wheel with a groove is continuously rotated, and under a certain amount of pressure of the compacting wheel, the billet is continuously dragged into the extruding die cavity which is composed of the extruding wheel groove, the guide plate and the die cavity by the friction force between the extruding wheel groove and the billet, plastic deformation takes place in the die cavity and the desired product is finally extruded from the die hole. The Rotary motion of the extrusion wheel is the main power source of continuous extrusion, which is realized by the friction between the billet and the groove of the extrusion wheel, the pressure in the extrusion chamber is over 1000MPA. H13 steel is the most widely used steel for this kind of continuous extrusion die due to its good red hardness, impact resistance and temper resistance under high temperature and high pressure. But long-term high-temperature and high-pressure conditions, easy to lead to die thermal fatigue cracking, hot melt loss, erosion, fracture and other failure forms. 1. Failure Die State and detection method failure extrusion wheel die is made of 600mm diameter H13 ESR Ingot, 200mm × 200mm square billet, then forged into 400mm outer diameter 232mm × 90mm inner diameter extrusion wheel billet. The extrusion wheel can be designed to extrude 50t copper alloy billets, but after 20t production, one side of the extrusion wheel groove falls off, and both sides of the wheel groove appear network cracks, as shown in figure 2.

The chemical composition of the die materials was determined by Arl4460 Direct-reading Spectrometer, the gas composition was determined by TCH-600 oxyhydrogen analyzer, and the microstructure of the die was observed by lecadm2700m metalloscope, non-metallic inclusions are evaluated according to GB/T10561-2005“Standard for determination of non-metallic inclusion content in steel grades”, the microstructure of H13 steel after quenching and tempering was evaluated according to the NADCA3207-2011 Die Steel Acceptance Standard Chart; the Rockwell hardness of the failed die was measured by statern200 automatic hardness tester; and the samples near the failure position of the extrusion wheel were taken, aUSTENITIZING at 1030 °C for 30 min in QSF-VF-1400T box vacuum heat treatment furnace, tempering at 600 °C for 2.5 h after quenching, and grain size grading according to GB/T6394 standard.

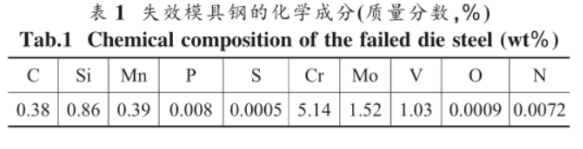

2. Test Results and analysis 2.1 composition determination of the chemical composition of the failure extrusion wheel is shown in Table 1. From Table 1, it can be seen that the failure extrusion wheel is composed of H13 Esr ingot material, and the contents of CR, Mo and V of the main alloy are in the middle and upper limits of domestic and foreign standards, the steel can meet the requirements of better strength, toughness and other high temperature properties in the use of extrusion die, and the content of P, s, O and n in the steel is lower, showing good metallurgical purity.

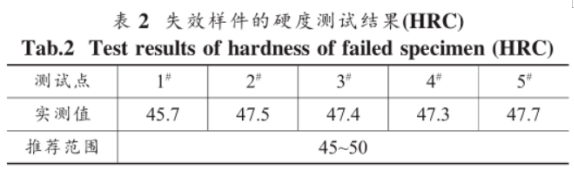

2.2 The hardness of the failure die is measured by using the ERNSTAT200 automatic hardness tester. The Rockwell hardness is measured from the surface to the interior of the cracked part. The results are shown in Table 2, the hardness at 1 # point near the surface is the lowest, and the hardness at the other 2 ~ 5 points is uniform. All the 5 test points are within the hardness range required by the copper extrusion die. Overall Mold hardness is normal.

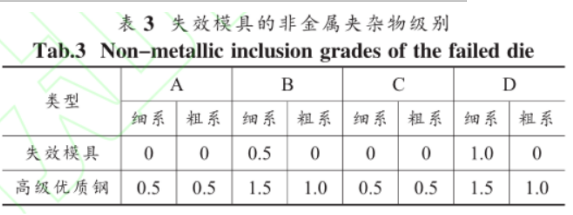

2.3 The most common micro-inclusions in H13 steel forgings after ESR are Al2O3 and its composite inclusions, TiN and its composite inclusions, etc. . Especially, the hard inclusions of magnesia-alumina spinel and titanium nitride will destroy the continuity and integrity of the Matrix, and have a negative effect on the comprehensive properties of the materials. After sampling and testing, the quality levels of Nadca # 207 standard medium and high quality steels were compared, as shown in table 3.

The failure die is mainly composed of a small amount of alumina inclusions and spherical inclusions of 5 ΜM grade, which fully meet the requirements of Nadca High Quality Steel Standard and reflect the better purity of the material, which is related to the low content of oxygen and nitrogen gas, and the effect of Electroslag remelting and refining. 2.4 The microstructure of the sample near the crack of the failure mould and the normal matrix of the mould was examined by LeicaDM2700M metalloscope after being polished and eroded by 4% nitric alcohol, as shown in Fig. 3.

As can be seen from figures 3(a) and (b) , the maximum depth of the crack is nearly 1mm, there is no obvious decarburization layer near the crack, the surrounding microstructure is homogeneous, there is no obvious zonal segregation and the microstructure is tempered martensite with normal quenching and tempering, the morphology of crack extension tip is similar to that of intergranular crack. As can be seen from Fig. 3(C) , the normal structure of the whole mould is tempered martensite. According to the map of heat treatment state of Nadca # 207-2011 standard, it should be HS5 qualified structure and the heat treatment structure is normal.

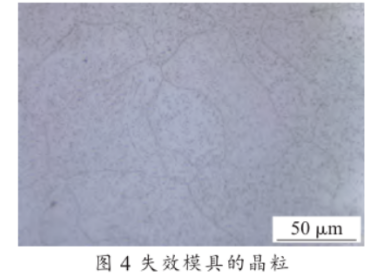

2.5 The normal zone samples near the crack of the failure die were tested for grain size, austenitized at 1030 °C for 30 Min, quenched and tempered at 600 °C. It can be seen from Fig. 4 that the average grain size of the die after heat treatment is 50μm, and the grain size is about 5.5 grade, which is obviously coarse grain, and can not meet the grain size requirement of grade ≥7 in GB/T24594-2009 high quality alloy die steel.

For quenched and tempered martensite TYPE H13 steel, grain coarsening has obvious adverse effects on the strength, plasticity and toughness of the material. The copper alloy extrusion wheel is subjected to high pressure friction and high temperature contact near the wheel groove, which belongs to the most severe working conditions in this kind of die, and has higher requirements for the strength and toughness of the material. Coarse grains and weak grain boundaries are bound to easily produce cracks and propagation cracks, leading to early failure of the die. 3. The conclusion and Suggestions for improvement (1) of the extrusion wheel groove into because organization coarse grain, coarse grain results in the decrease of mold material tenacity, especially in the condition of wheel groove area conditions, under the effect of high pressure, high temperature and friction force, easy to produce cracks and extend, falling under the copper billet friction adhesion, is the one inducing the inefficiency of extrusion wheel. (2) There are no obvious abnormalities in the chemical composition, non-metallic inclusion, hardness and microstructure of the die material. The heating system should be strengthened to control the forging process of materials to prevent the austenitizing temperature of materials from being too long, resulting in obvious grain growth. After forging, superfine cooling process can be controlled to refine grain, improve material strength and toughness, and avoid coarse grain.

Source: Special steel processing and application